Introduction

Choosing the right material in packaging is vital in the protection of goods’ quality, visibility of brands and the packaging as well as support to the products’ durability. There are two broad categories namely rigid packaging and flexible packaging both having their merits depending on their use, handling, and storage in relation to the products concerned. Here we will define what is meant by the concept of rigid packaging, and also learn about the unique benefits of its usage.

Understanding Rigid Packaging

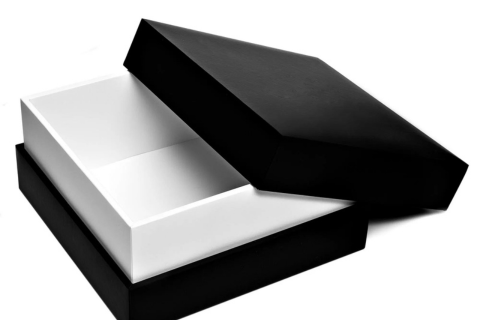

Rigid packaging comprises packaging that does not have a flexibility factor and is made from materials that does not have a flexibility factor. Rigid packaging is normally used for products that need protection and shape control and can be made from glass, metal and hard plastic. Tight packages-moving packagings, containers and cases including boxes, bottles, jars, tubs are most appropriate to protect fragile.

Rigid plastic is the most common material used in this type of packaging because it provides the necessary level of protection, attractive appearance, and small mass. Other materials, including cardboard and glass may comprise rigid packaging to develop variable solutions across the food and beverage, electronics, and cosmetics sectors.

Main Features for Rigid Packaging

When considering what is meant by rigid in packaging, it’s essential to understand the attributes that define its structure:

Shape Retention

Rigid packaging maintains a steady shape and structure due to the pressure exerted on it and the product packed inside cannot harm or disfigure the packaging.

Durability

Since plastic and glass as the materials used in this type of packaging are rigid this type of packaging offers an impact protection which is important for delicate products and those that require longer shelf life.

Enhanced Presentation

From the perspectives of packaging shapes and strength, rigid boxes are closely associated with better branding, labeling and finishing that gives firmness to products giving a look that can easily capture customers’ attention in retail stores.

Common Applications of Rigid Packaging

Sclerometre packaging is widespread in the dispersing of goods which need to be tightly sequestered in a stiff and stable manner. Some common applications include:

Food and Beverage

Permanent packages like; Glass bottles, jars and cartons are used to pack delicacies that need to be well protected like sauces,juice and snacks.

Cosmetics and Personal Care

Cosmetics manufacturers often employ the use of rigid packaging for creams, fragrances, and powders, these products require sturdy packaging to effectively uphold the execution of functionality and image.

Electronics

Solid formations are also necessary for fragile electronics like hand-held phones, earphones, cameras as well as the smartphone industry to prevent damage or incidental destruction during transportation.

Rigid vs. Flexible Packaging: Understanding the Difference

Although it gives strength and shape stability rigid packing is made up of materials such as metal, glass and plastics while flexible packing is made up of plastic films, foils and paper and they are flexible as they can bend and fold along the shape of the packed commodity. These are believed to be more convenient than rigid forms of packaging because they are light in weight as well as are more compact in size. Below is a breakdown of how rigid is to be flexible and how stability is to adaptability and the advantages and disadvantages of each offer.

Advantages of Rigid Packaging

Product Protection: Such custom packaging offers a good barrier against shock, humidity, and contaminants hence used in the packing of delicate, massive or expensive products.

Premium Appearance

It has a nice surface that can be easily decorated or embossed, which can affect brand image and same goes for the Luxury segment.

Extended Shelf Life

describe many rigid containers as having an additional protective feature of increasing product shelf life and thus reducing wastage.

Reusable and Recyclable

Rigid packaging mostly incorporates recycled material which makes it have the benefit of environmental conservation.

Decision Making between Rigid and Flexible Packaging

It is finally the decision whether it is better to use rigid or flexible packaging, all depending on the peculiarities of the product and your company’s concerns. Here are some factors to consider:

Product Sensitivity

If your product is delicate or needs protection more than others for instance glasses or electrical devices then rigid packaging is appropriate. When it comes to products which require less protection due to its fragility then flexible food packaging may be the best way forward, it is ideal for packing chips or granola.

Storage and Transport

If space is a factor that cannot be overlooked, as with foods that have a short shelf life, then flexible packaging provides sizable returns on space. Nevertheless, rigid containers are more appropriate for products which require more support in terms of handling.

Brand Perception

Glossy and hard materials share the ability to provide a more luxury image, and are common in luxury brands. Nonetheless, flexible packaging represents a versatile appealing strategy, appropriate for the brands that aim for convenience and franchised convenience, environmentally conscious.

Sustainability Goals

The cause and effect of rigidity and flexibility is not dependent on the environment since they can both function in the protection of the environment by use of appropriate materials. Conventional packaging material such as tin, glass, or aluminum are recyclable though new flexible packaging material has also evolved with the concept of recycle and biodegradable packs.

Why Swift Print Pack Recommends Rigid Boxes to Make Your Product Look Best

We as Swift Print Pack understand that both the Rigid and Flexible packing hold their importance but when it comes to higher protection and elegant look the Rigid Boxes are best. Firstly, it provides stringent constructiveness and elasticity of the design structure, and probabilities for supporting high-end branding, that makes rigid box an appropriate choice for luxury products. If you want packaging that can create a strong impact on consumers, rigid boxes are a perfect choice especially when they are used to package and protect your brand from being moved unconsciously, because they stand as a sturdy and elegant packaging material.